A pipe cutting machine is plumbing equipment that is used to cleanly cut out the pipes to the shapes it is requested to be in. This equipment is a modern technique used to cut out the pipes with precision and efficiency making the whole process faster and cleaner than the old tradition of cutting pipes through a hacksaw. This process of cutting pipes through a machine follows a principle of both the digitalization used by a computer and the ultimate use of hydraulic pressure.

Explain the uses of different parts of this pipe cutting plumbing equipment-

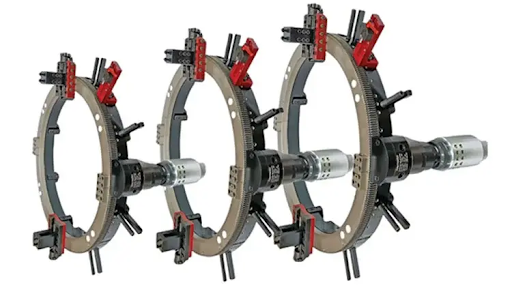

- The stainless steel round or semi-circle blade is enclosed within a blade case which helps the operator to be safe from the metal flames or fragments coming in contact with the operator.

- The blade of the hydraulic pipe cutting machine can cut fast through steel, iron which is ductile, cement, concrete slabs or other units, plastic pipe, etc.

- The blade of the machine can cut through the wall to reach a maximum depth of about two inches.

- The stainless steel blades used for cutting through the pipes with the use of hydraulic pressure usually are available in two types that is carbide tipped where the stainless steel saw blades are brazed with carbide mainly used material is tungsten carbide or titanium carbide. The most commonly used saw blades in these cold pipe cutting machine are tungsten carbide as they are able or have the power to cut through everything available like asbestos, aluminum, insulation, rubber, plastics, paper, stainless steel, etc.

- A hydraulic pipe cutter can easily cut through pipes that fall under the range of diameter of six inches to ninety-six inches.

- All types of pipe cutters are versatile and portable which they can be used in workshops and on-site repair work. The different types of cuts that can be done are bevel cuts, changing the face of the saw blade to any other angle but not a 90-degree angle then the cut will be a bevel cut; chamfer cuts, a cut made on the edge get both angled and straight slope, and straight cuts are simple 90-degree cuts to separate a single piece into two halves.

How are hydraulic pipe cutters different from others like manual cutters or electrical cutters?

Hydraulic pipe cutters squeeze down the area which needs to be cut down especially used for cutting down the soil pipes which carry drains and wastewater. Pressure is applied in the area for a smooth and précised performance with the use of high force. These pipe cutters get lubricated through their machinery so which makes the blades remain sharp and long-lasting.

How to choose the right pipe cutter?

- First and foremost is the purpose all pipe cutters can’t cut through all the materials like copper, aluminum, iron, etc.

- Second is the pipe diameters you deal with and it is better to choose mechanical or automatic pipe cutters as they require a lot of pressure to cut through the hard and durable pipes.

To conclude, the above article clearly illustrates the usage and purpose of hydraulic pipe cutters which can finish up the job in seconds but with precision and safe for the operator.